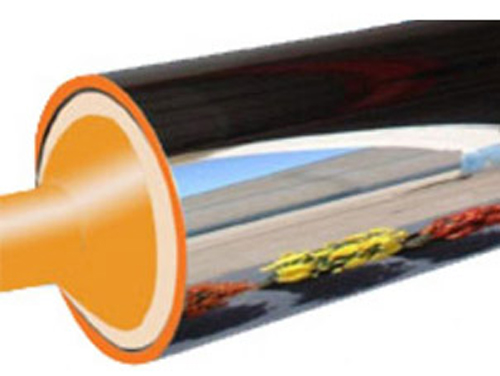

The roller is also called the roller. The roller is a cylindrical part. It is divided into a driving roller and a driven roller according to its purpose. According to the driving method, it is divided into a power roller and an unpowered roller. The power roller is divided into a single sprocket roller and a double sprocket roller. , Single O belt roller, double O belt roller; unpowered rollers are divided into inner tooth rollers and spring press-in rollers. According to the structure, it is divided into cylindrical roller and conical roller.

Rollers are widely used in various transmission and conveying systems and sorting and conveying equipment such as rotary screen printing machines, digital printers, mining conveying equipment, papermaking, packaging machinery and so on.

It is usually made of seamless steel pipes, and depending on the process needs, such as aluminum alloy 6061T5, 304L/316L stainless steel, 2205 duplex stainless steel, steel castings, and solid forged alloy steel cores are used as materials.

The production of rollers mainly consists of the initial turning of the roller body, initial static balancing, shaft end interference assembly welding, fine turning and fine dynamic balancing. If the geometric tolerances such as roundness, cylindricity, and straightness are required to be less than 0.2mm, they need to be ground on a cylindrical grinder or roll grinder after finishing. If the surface hardness is required, it is necessary to increase the heat treatment process.

After the roller is formed, in order to prevent rust and corrosion, wear resistance and support, it also needs surface treatment or coating such as painting, galvanizing, TEFLON spraying, rubber coating, chrome plating, ceramic spraying and oxidation.