The internal bearing and shaft head structure of the rubber roller is very precise, and a slight difference will directly affect the use effect. If the lubrication of the bearing and the shaft head is not very good, it is easy to cause abrasion, and it will seriously affect the quality of the rubber roller, thereby affecting the quality of the product.

The use and maintenance of rubber rollers

1. The pressure between the rubber rollers is too heavy. The pressure between the rubber rollers is too heavy, which will increase the friction between the rubber rollers, make the rubber rollers heat up and heat, increase the squeeze expansion between the rubber rollers, and accelerate the aging and Deformation speeds up the emulsification process of ink and water, which is not conducive to the transfer of ink.

The solution is: the pressure between the rubber rollers should be basically the same as the pressure on the contact plate. The experience is to use a 1500-thread, 3cm-wide plug piece inserted between the test rubber rollers, and you can feel a certain tightness.

After scrubbing, wipe it again with a clean cloth and then install the rubber roller on the machine to facilitate the next use.

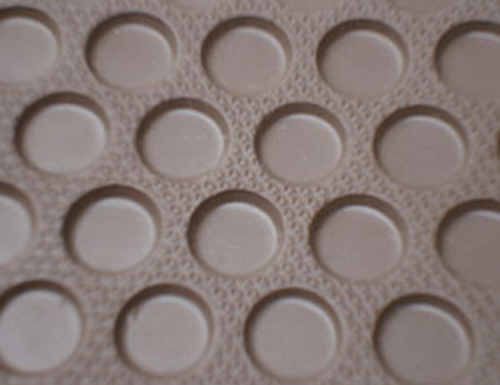

2. Treatment of surface crystallization of the rubber roller. Surface crystallization closes the pores on the surface of the rubber roller, which will make the rubber roller lose its ink affinity, resulting in uniform ink transfer and easy emulsification of ink.

The solution is: remove the rubber roller on the machine, lay it flat with a shelf, stick the cloth with kerosene and pumice powder, rub the surface of the rubber roller evenly and wipe off the crystalline layer on the surface of the rubber roller, showing the original For the rubber color of the rubber roller, use car wash water or gasoline to clean the kerosene and pumice powder remaining on the rubber roller, reinstall and adjust the pressure of the rubber roller.

3. Maintenance of the bearing on the rubber roller During the high-speed operation of the machine, the bearing on the rubber roller wears out very obviously, especially if the operator usually piles up the bearing maintenance cloth to pay attention, the wear is even worse. After the bearing of the rubber roller is damaged to a certain degree, the rubber roller will bounce friction and squeeze, which will shorten the service life of the rubber roller. And it will cause the phenomenon of "ink and water streaks" in the printed product. Therefore, the operator is required to remove the rubber rollers every week, grease the bearings, and replace the bearings that are so worn out or rotate poorly to ensure the normal use of the rubber rollers.

4. The influence of the rubber roller stacking in the workshop environment. In the production of hot and humid weather and dust from the surrounding environment, the high-speed operation of the machine causes the surface temperature of the rubber roller to continue to rise, and the rubber roller heats up and expands, increasing the glue. The friction of the roller will shorten the service life of the rubber roller.